Push-lock fuel lines play a crucial role in fuel system maintenance, connecting the tank filler neck to the carburetor or throttle body and facilitating fuel supply to the engine.

These lines are engineered to prevent fuel leakage during refilling operations and halt fuel spillage during vehicle repair tasks like changing oil filters. However, they can sometimes become stuck and challenging to remove.

This article provides a comprehensive guide on detaching a push lock fuel line without needing any specialized tools, a handy skill for DIY car maintenance.

Contents

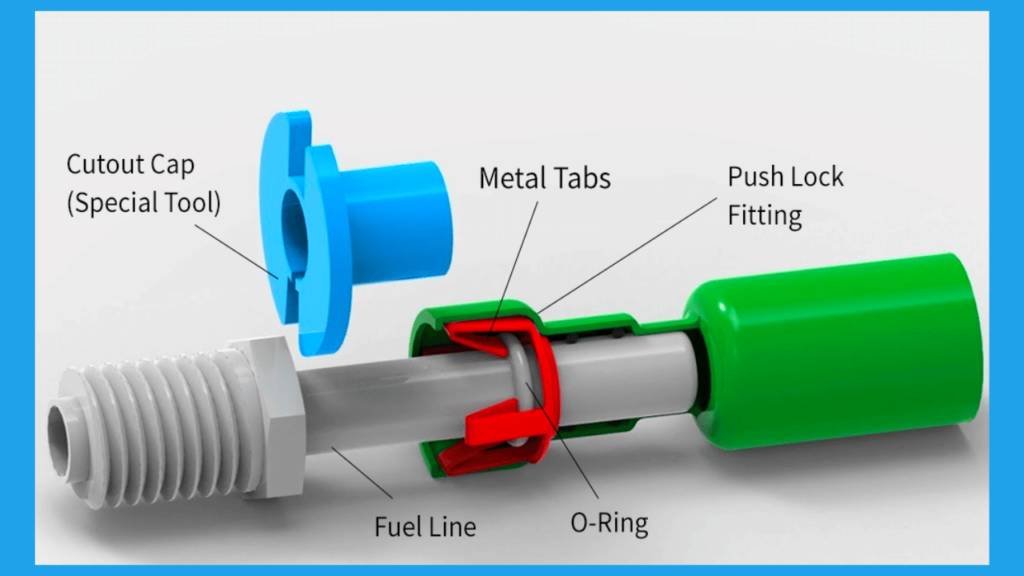

Understanding the Push Lock Fuel Line Design

Before you attempt to remove a push lock fuel line, it’s essential to comprehend its structure and design—the push lock features four metal tabs on the inside, made of spring steel.

These tabs need to be pushed to unlock. Conversely, the fuel line has small spring tangs or O-rings fitted on its outer lip. When the push lock is slid onto the fuel line, these metal tabs are pushed by the spring tangs on the fuel line and become locked in place. Removing the push lock is impossible without something to push these metal tabs.

Step-by-Step Guide to Detaching a Push Lock Fuel Line

Empty the Fuel Tank: Before you start, ensure the fuel tank is empty to prevent fuel spillage and ensure a safer process.

Remove the Safety Clip: The safety clip prevents the fuel line from falling loose. It needs to be removed from the fittings.

Measure the Diameter of the Fuel Line: Fuel lines come in various diameters in different vehicles. Measuring the diameter of the exposed fuel line is crucial to ensure the correct size O-ring tool is used.

Use an O-ring Type Special Tool: This plastic tool, featuring a cutout on one side, safely removes the fuel line by depressing the tabs inside the push lock. Although you can make this tool at home, purchasing a ready-made one is safer to avoid damaging the fuel line or causing a fuel leak.

Snap the Tool Over the Fuel Line: After selecting the correct size O-ring tool, place it onto the fuel line and push it inside the push lock fitting. This action will push the metal tabs inside the push lock, allowing the fuel line to be removed.

Pull the Fuel Line Out: Gradually pull the fuel line out of the push lock. If a spring tang or O-ring inside the lock fitting sticks to the fuel line, turn the fuel line back and forth to work it out slowly.

Reinstall the Fuel Line: Once the required job is complete, reinstall the fuel line by pushing it

and the fittings in opposite directions until they click into place. Tug at the fuel line back to ensureit is properly seated.

Read also: Should I Trade In My Car Or Sell It?

Tips and Precautions

- Always ensure the fuel tank is empty before removing the push-lock fuel line.

- Please keep track of the length of the exposed fuel lines when removing them to ensure proper reinstallation.

- Be careful not to damage the threads inside the tank when removing the push-lock fuel line.

- Use the correct size O-ring tool to avoid damaging the fuel line.

- Exercise caution when working with fuel lines, as they can be dangerous and cause severe injury or property damage if mishandled.

- Wear safety goggles and gloves when working with fuel lines to protect your eyes and skin from potential spills or splashes.

- Suppose you’re unsure of your ability to remove a push-lock fuel line safely and correctly. In that case, it’s best to consult a professional mechanic or auto technician to avoid potential hazards or damage to your vehicle.

Conclusion

In conclusion, push-lock fuel lines are designed to prevent fuel leakage and spillage during maintenance procedures. However, they can become stuck and difficult to remove. With this step-by-step guide and the use of an O-ring type special tool, you can easily remove a push-lock fuel line without the need for any special tools. Always exercise caution and follow automotive safety precautions when working with fuel lines to ensure a safe and successful process.